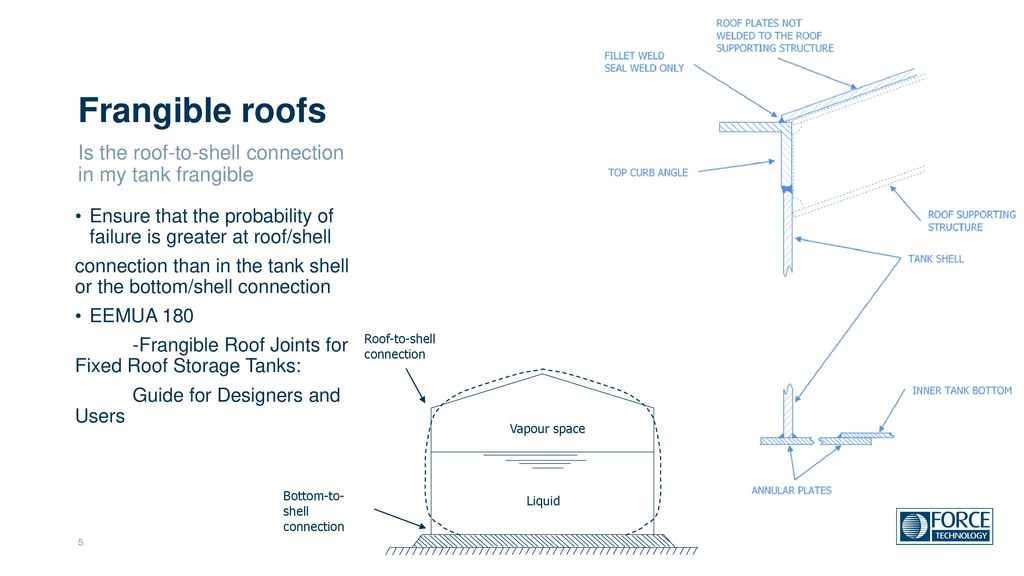

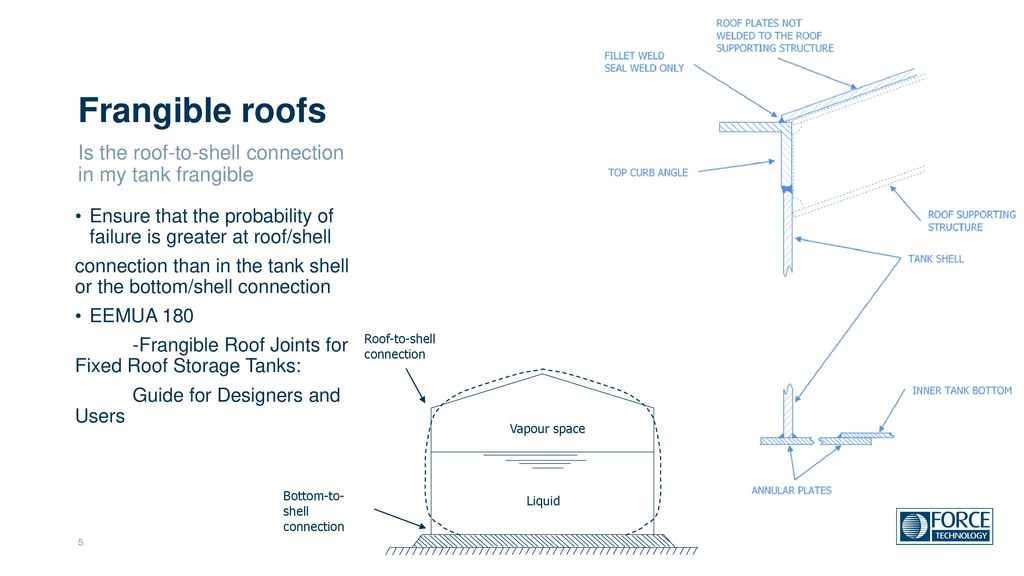

In such tanks the roof to shell joint is intended to fail in the event of overpressurization venting the tank and containing any remaining fluid.

Frangible roof tanks.

4 8mm thick plate a.

In the event of over pressurization the frangible roof to shell joint is designed to fail before the tank shell or the shell to bottom joint.

Frangible roof tanks are also vulnerable to damage if overfilled.

Api 650 gives rules for the design of frangible roof joints in fluid storage tanks.

Even when using a frangible roof however some owners still.

By way of example for a tank having a diameter of 20 feet 6 lm a shell of 3 16 in.

However in the context of tanks the word has a specific meaning and is defined in the main tank construction standards bsen 14015 and api650.

This failure is intended to vent the tank and contain any remaining fluid.

Thus appropriate measures wellknown to tank designers are required to insure that the liquid level in the tank does not rise above the top straight side of the tank.

For reasons discussed above many tank owners prefer to satisfy emergency venting requirements with a frangible roof particularly for tanks without a floating roof because of the frangible roof s potential to vent deflagrations without substantial damage to the shell or bottom.

By way of example for a tank having a diameter of 20 feet 6 lm a shell of 3 16 in.

The concept of frangible roof only applies to flat bottom cone roof tanks with limited roof apex angle.

1 evaluation of the area inequality as a method to predict the buckling response of the compression ring 2 effect of roof slope tank diameter and weld size on the frangible joint and 3 effect of the relative strength.

Frangible is a word that means easily broken.

Eemua 180 gives guidance to designers and users of such tanks on the practical steps that can be taken in design operation and maintenance to predispose the roof to shell joint to fail in preference to the shell to bottom joint thereby ensuring retention of the tank s contents.

Frangible roof tanks are also vulnerable to damage if overfilled.

4 8mm thick plate a.

Describes research that evaluates the ability of the present api 650 tank design criteria to ensure the desired frangible joint behavior.

Thus appropriate measures wellknown to tank designers are required to insure that the liquid level in the tank does not rise above the top straight side of the tank.